Central laboratory

* Pflichtfelder

Diese Angaben sind zur Anmeldung zum Newsletter "Packendes" notwendig.

It’s essential to pick the right material and design. Our central laboratory carries out regular checks to ensure that base material and finished packaging are up to the job. Klingele products must comply with your stringent quality standards – and our own – and guarantee that your product reaches its destination safely.

As early as the development phase, all materials are subjected to current test procedures – such as bursting strength (BST), puncture effort (PET) and edge crush resistance (ECT) – under standardised conditions and using the latest equipment. Depending on transport conditions and requirements, finished packaging is also subjected to box crush testing (BCT).

We are recognized as testing laboratory for hazardous goods packaging by Germany's Federal Institute for Materials Research and Testing (BAM). This means flexible, economical, faster execution of the entire testing and approval process for your corrugated packaging for hazardous substances.

You can rely on Klingele: your products – even hazardous goods – are in safe hands.

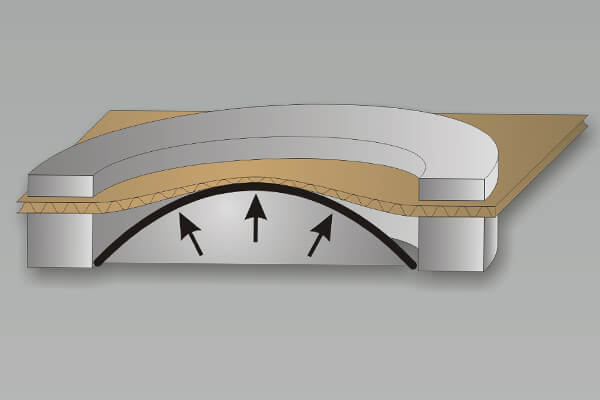

To test corrugated board bursting strength, an elastic membrane is filled with liquid and pressed against the board sample until the board bursts.

The maximum pressure is an expression of the burst resistance of the material – in this case, the corrugated board.

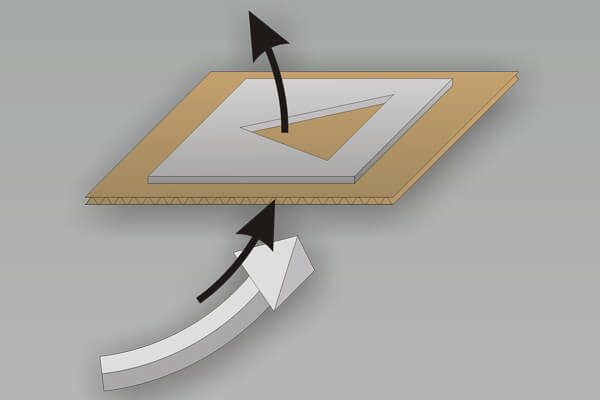

The term puncture effort defines the energy a standardised triangular punch requires in order to completely penetrate the test material (here: corrugated board).

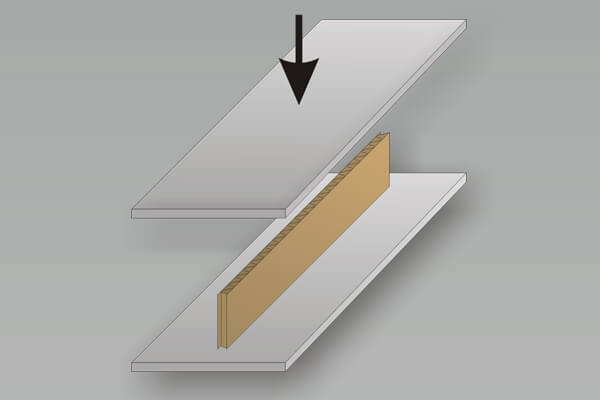

The edge crush test defines the resistance that an upright sample of the material on trial – in this case, corrugated board – presents to a force bearing on it before collapsing. The material sample must be of predefined size.

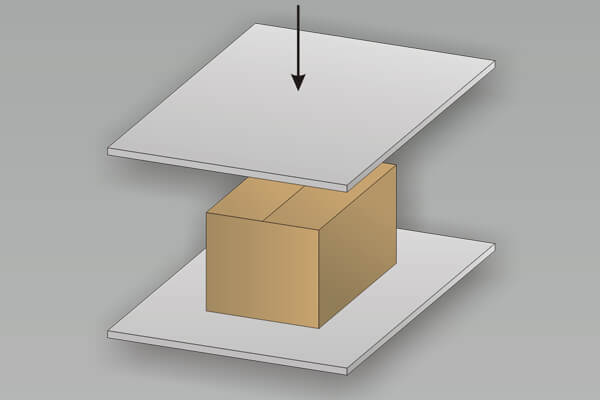

The box crush test is an indicator of packaging stability.

This value quantifies the force that the packaging can absorb and pass on.