Corrugated board

production

* Pflichtfelder

Diese Angaben sind zur Anmeldung zum Newsletter "Packendes" notwendig.

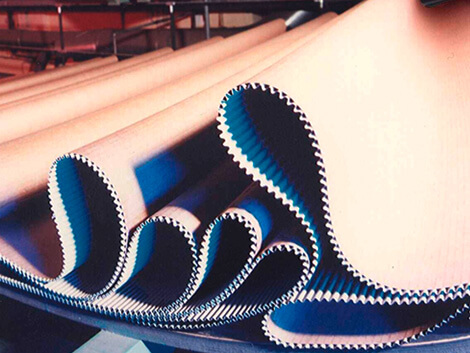

Corrugated board or fibreboard consists of at least three layers of paper: one fluted (corrugated) web and two flat liners. The corrugated web element is sandwiched between the inner and outer liners and glued.

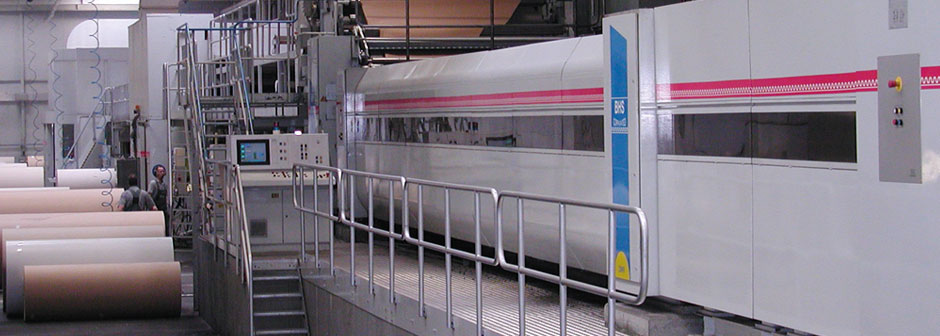

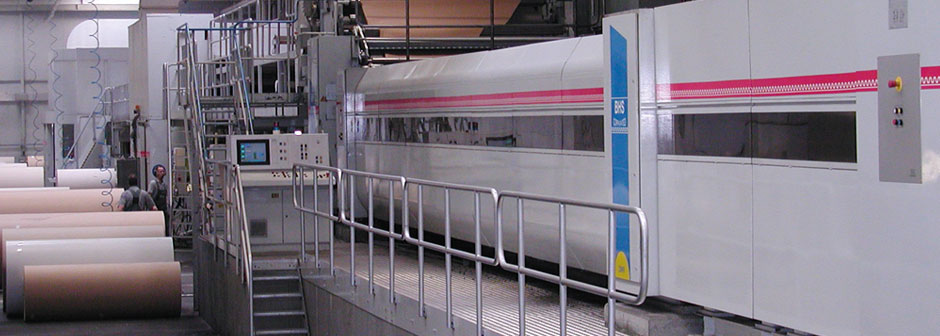

Our corrugated board is made from what is known as base paper, which is selected according to the requirements of the customer and of the product to be packed. For the base paper to become finished packaging, it passes through two or more manufacturing processes, depending on your packaging requirements.

The corrugator produces the hallmark fluting of corrugated paper. First, the paper is heated and moistened to make it pliable, and then it is corrugated by passing it between two fluted rollers at high pressure. After starch-based glue has been applied to the crests of the flutes, the corrugated paper passes between a fluted press roller together with the inner liner or lining paper to form single-wall corrugated board. Further corrugated or flat paper layers may be added to form multi-wall board.

The board produced in the corrugator, cut to size and creased, is now converted into packaging on processing machines such as flexo folder/gluers, flatbed die-cutters, rotary die-cutters and box folder/gluers. A vast number of different shaped boxes, diecut packaging, displays and many other options in all sorts of sizes are possible.

We employ numerous printing techniques e.g. flexoprinting straight onto the board, pre-prints on paper or offset laminations, or surface treatment processes such as embossing, coating or impregnation which – combined with our specialist know-how – turn an ordinary piece of packaging into an attractive package that helps to sell your product.