Jetzt zum Newsletter "Packendes" anmelden!

* Pflichtfelder

Diese Angaben sind zur Anmeldung zum Newsletter "Packendes" notwendig.

Our D flute – the flute of success

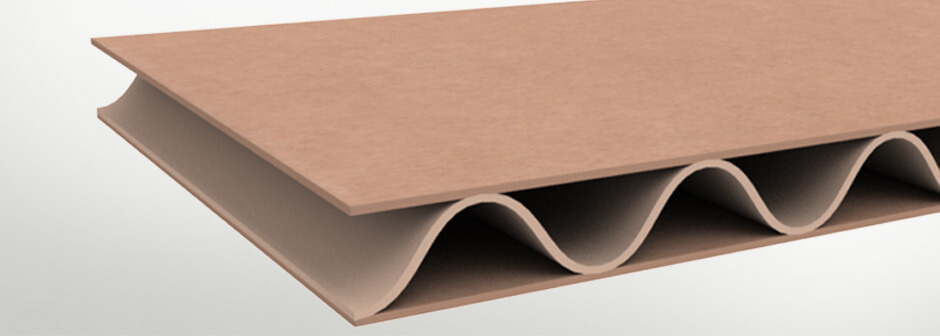

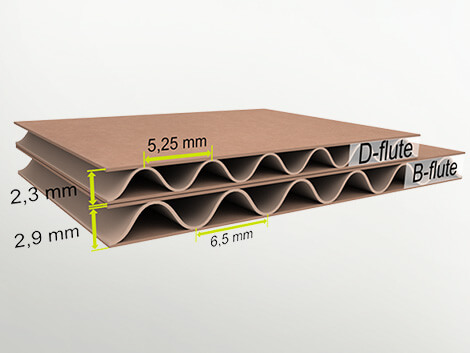

With a height of 2.3 mm, the D flute fills the gap between the B and E flutes. Thanks to its smaller thickness, 26% more corrugated board blanks can be stacked on a pallet compared to the B flute. Fewer pallets are required – thus reducing handling, storage and transport costs and the carbon footprint. As a result of its considerably better flat crush value than the B flute, our D flute can be produced using lighter paper. Huge logistics savings and lower resource consumption means more protection for the environment. Our D flute is perfect for a wide range of product packaging in the food industry, including UHT milk trays and for jars, cans and bottles. Its improved print surface also makes our D flute an attractive alternative when the advertising ability of secondary packaging is important. In addition, it offers clear advantages in terms of the folding precision of corrugated boxes and is therefore an appealing option for use in packaging machines.

Properties/advantages

The exceptional properties

- The D flute fills the gap between the B and E flutes

- Corrugated profile 2.3 mm smaller than the B flute

- Corrugated pitch 5.25 mm smaller than the B flute

- Very good flat crush values

The impressive customer benefits

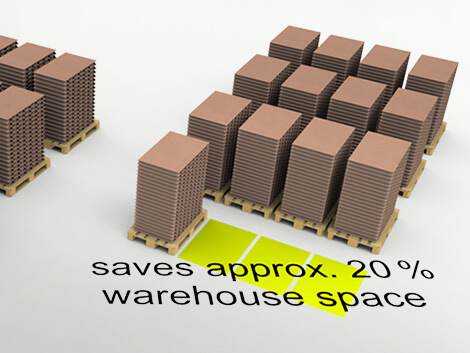

- 26% more corrugated board blanks on the pallet

- 20% more warehouse space

- Reduced handling requirements

- Better print surface

- Higher folding precision

Lower resource consumption means more protection for the environment

We continuously strive to optimise our packaging concepts with regard to the use of material and natural resources. With the D flute, we offer a slim, yet sturdy corrugated profile with an extremely sustainable character. And it’s not only customers who reap the benefits of huge logistics savings with the D flute. We, too, require less cargo space and thus produce fewer pollutants during road transport.

Areas of use

In light of its product specifications, the D flute is suitable for very specific areas of use. Packaging of products in the food industry, which are capable of withstanding the load of products stacked on top.

- Drink trays

- Deep-frozen goods

- Cans

- Glass bottles

- Shelf packaging